snacks processor

| Payment Terms: | T/T |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No.:

AFC-DL

Production Capacity:

100

Delivery Date:

30 days

Processing:

Frying Machine

Means of Transport:

Ocean

Packing:

wooden case

Processing Types:

Snack

Brand Name:

AFC

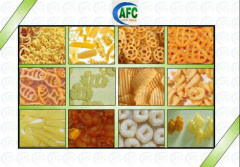

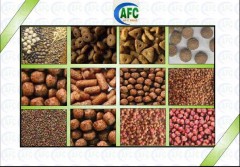

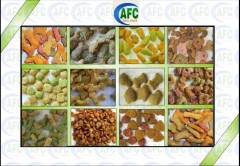

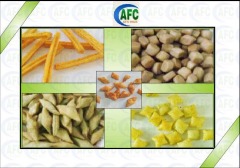

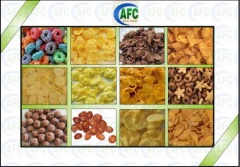

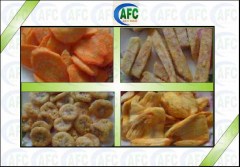

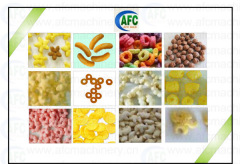

These products by changing the dies can make various shapes of food, such as spiral, potato chips, shrimp chips, shells, round pipes, rings, wave

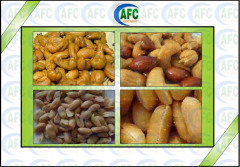

This Snack food process line adopts potato starch, corn starch, cassava starch, wheat flour, as main materials through single-screw inflating extruder to produce various shapes of snacks food, such as spiral, potato chips, shrimp chips, shells, round pipes, rings, wave ,bugles and so on.After drying it need to frying to get expanded and crispy snacks food,which are popular in the market. This line is characterized by unique technique, rational configuration, high automation and stable performance.

Series of snacks food manufacturing facility consist of feeding, extruding, cutting, heating, lubricating and controlling system, mainly used for processing of fried pellets and snacks.

Frequency-conversion controlling to gain powerful drive, stable perform, and electricity saving.

Model: AFC-DL

Installed Power: 380V/415V

Output: 80-120 KG/H

1.Mixer

Installed Power: 380V/415V

Output: 80-120 KG/H

1.Mixer

2.Single-screw Extruder

3.Pulling Cutter

4.Cooling

5.Drying Box /(Dryer)

6.Automatic Frying Machine

7.Flavoring System

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Snacks Machines

Snacks Food Machines

Snacks Food Machinery

Snacks Food Extruder

Food Processor

Film Processor

More>>

Find more related products in following catalogs on Hisupplier.com

Related Products

Company Info

Shandong AFC M&E Co.,Ltd [China (Mainland)]

Business Type:Manufacturer

City: Jinan

Province/State: Shandong

Country/Region: China (Mainland)

You May Like:

Product (200)

- food processing line (161)

- Others (39)